Travertine is a natural rock, which is one of the varieties of calcareous tuff. This stone has a fine-grained structure, which allows it to withstand the effects of adverse climatic conditions for a long time. In the classification of mineral formations, travertine is located in the gap between limestone and marble. Having strength indicators similar to marble, travertine, however, is easier to process, and its extraction is much cheaper. The popularity of travertine is due to its durability, aesthetic appearance and relatively affordable price.

Travertine has been used in construction for a very long time. One of the most famous buildings built of this stone is the Colosseum located in Rome. A striking example of the durability of travertine is the fact that the first bridge built in Rome has not yet collapsed under the influence of time. Currently, there are many more practical and inexpensive materials, which is why travertine is mainly used in modern construction for decorating interiors and facades.

Travertine has a porous structure, which is why it is one of the lightest natural stones. In addition, this stone has good sound and thermal insulation properties. Despite a certain tendency to absorb moisture, travertine withstands temperature changes well and does not collapse under the influence of the freeze-defrost cycle.

What is travertine in its chemical composition?

The main mineral in travertine is aragonite with a low calcite content. A significant proportion is accounted for by calcium oxide, the content of which can reach up to half of the total mass of the stone. From 5 to 10% of the composition includes silicon dioxide, as well as oxides of various metals.

Travertine is formed during the precipitation of chemicals dissolved in water. Many different factors are involved in the process of stone formation, which ultimately affect the appearance and physical characteristics of the stone. It is worth noting that during mining, the stone can change its color under the influence of atmospheric oxygen, which oxidizes the metal salts contained in the formation. In addition to purely visual characteristics, the color of travertine also indicates its strength: a lighter stone is usually less resistant to mechanical stress than a dark one.

What are the types of travertine?

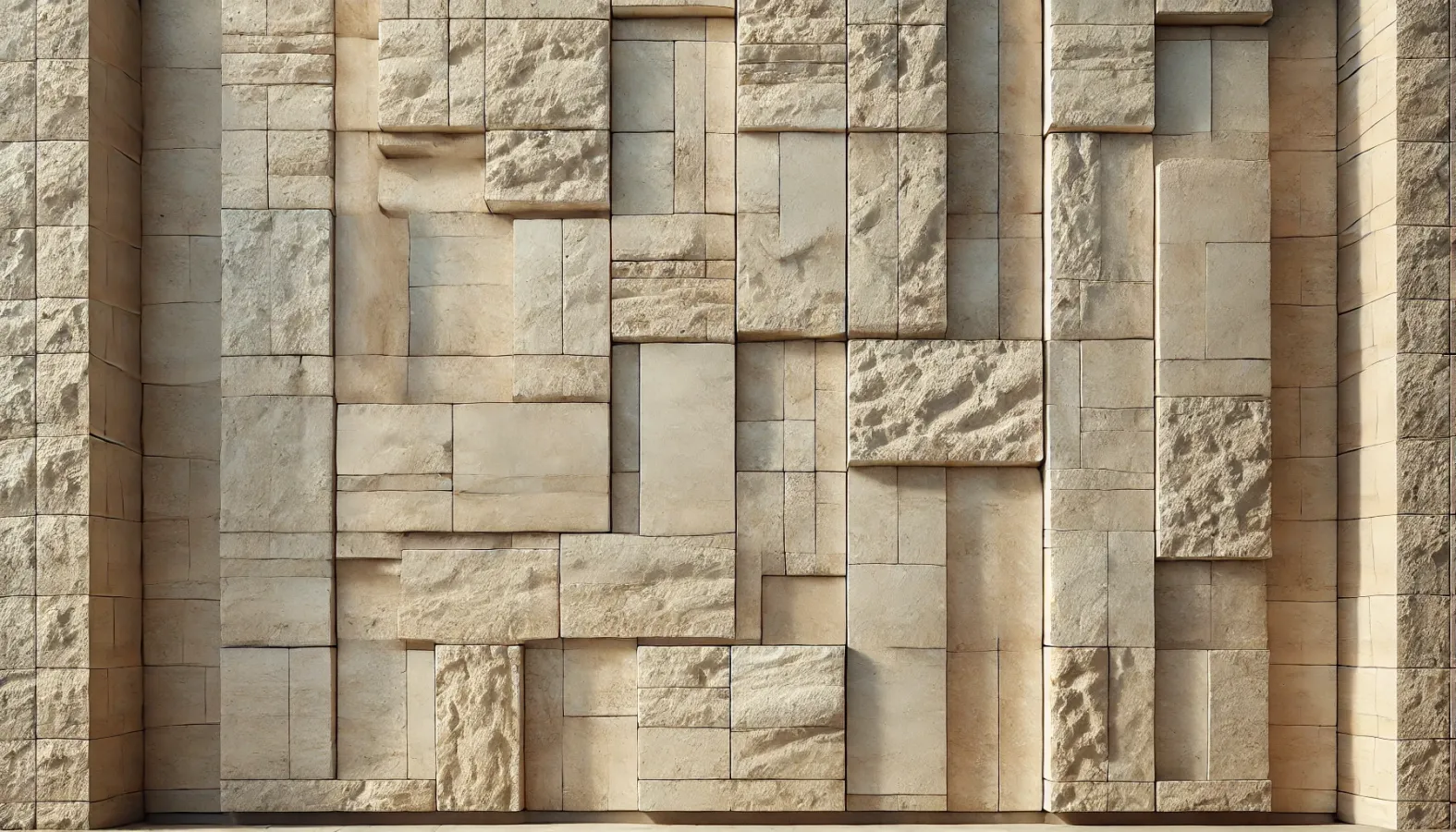

Travertine can vary in color, which varies in a fairly narrow range of pastel tones, as well as the degree of porosity of this material. In its original form, travertine is practically not available for sale, which is why the main way to divide this material into varieties is classification by processing method. The following methods are used for processing travertine:

- Polishing allows you to make the initially rough surface of the stone smoother. In the process, the stone is covered with a protective adhesive layer, which reduces the water permeability of travertine and allows it to be used in the cladding of bathrooms, saunas or baths. Individual grades of polished travertine can even be used for finishing pools. This material is no less in demand when facing dry rooms. Polished travertine is easy to care for and is not prone to accumulation of dirt.

- The travertine floating is carried out using a grinding wheel, the purpose of this procedure is to align noticeable differences in the surface of the stone. At the same time, the stone retains a matte, slightly textured surface of natural color. Polished travertine can also be used for the manufacture of floor coverings, as it is quite rough.

- Travertine grinding is aimed at eliminating strong differences in the cut of the stone. At the roughing stage, water cooling and coarse-grained sand are used for grinding, which serves as an abrasive material. Finer grinding is performed using special tools with a gradual decrease in the fraction of abrasives. The thoroughness and duration of grinding depend on the purpose of the final product.

- Bucharding, unlike the previously mentioned methods, has a diametrically opposite goal – to make the surface of the stone more rough. Such processing is carried out with sawn travertine slabs using special machines. In the process, the surface of the stone is heated and then chipped with impact heads. The working nozzles can have different shapes, which allows you to vary the resulting texture.

- Brushing is performed using special hard brushes. At the same time, small particles of stone are chipped out, which makes it possible to form a matte, textured surface. With this processing method, the natural texture of travertine and the unique features of the pattern of this stone are most clearly manifested.

In modern design, the so-called "natural chip" is often used. This decoration option involves the use of sawn stone, the outer surface of which is chipped by hand to simulate natural rock. In addition to various methods of mechanical action, the surface of travertine is often treated chemically, which increases its resistance to dirt and moisture.

Despite a number of undeniable advantages, natural travertine is not without its drawbacks. First of all, this material needs special care, without which its appearance will quickly become unsightly. This is especially critical for bucharded or brushed travertine, which has a considerable tendency to accumulate dirt deep in the porous surface. In addition, natural stone requires a lot of labor from the beginning of its extraction from the quarry, which automatically means a considerable cost of the finished product. For this reason, a more economical analogue of natural mineral formation is more often used – artificial or liquid travertine.

How is travertine made of artificial origin?

Strictly speaking, this material can be called artificial with a fair degree of conditionality, since 90% of its composition is crushed natural stone mixed with a binder based on copolymers. When using this method, the formation of the desired texture of the material is achieved not by using mechanical processing, but by pouring a liquid mixture into a mold.

In addition to the manufacture of facing tiles in the factory, liquid travertine can be used as plaster directly on the construction site. The result is a convincing imitation of a natural material, hardly distinguishable from natural stone visually and tactilely.

The aesthetics of this material are perfectly complemented by its performance characteristics. Liquid travertine does not fade over time and retains its original color. In addition, this material has a high elasticity threshold, which gives it good resistance to vibration. From the point of view of moisture resistance, artificial travertine even surpasses natural, due to the binder additives present in the mixture. This type of wall covering has other advantages, such as:

- Environmental friendliness. Artificial travertine for the most part consists of natural ingredients and is completely free of toxic impurities. This material can even be used for lining the inner walls of medical institutions and catering establishments.

- Endurance. Travertine plaster tolerates the effects of vibration and seismic shocks well, and is also resistant to mechanical damage.

- Resistance to climatic effects. Like natural stone, artificial travertine is practically not exposed to ultraviolet light. In addition, this material tolerates strong temperature changes well and is not sensitive to moisture.

- Fire resistance. Travertine is characterized by high fire safety, as it is completely made of non-flammable components.

- Versatility. Liquid travertine plaster can be applied to any surface, up to metal and glass.

- Durability. Subject to the relevant technological standards, the facade lined with liquid travertine can go without repair for 30 years or more.

The use of travertine

The combination of the above factors makes travertine a popular material with an extremely wide range of applications. The most common use of travertine is in areas such as:

- Facade cladding. The combination of aesthetic appearance and practical physical and technical characteristics makes travertine an excellent choice for covering the exterior walls of buildings.

- Floor and sidewalk tiles. Travertine has good abrasion resistance and does not slip when wet.

- Interior wall decoration. Both natural and artificial travertine have an aesthetic appearance and open up a wide scope for the implementation of original design ideas.

- Production of decorative elements. Cornices, columns, balusters and other travertine decorations are used to create the aesthetics of a building in a classical architectural style.

- Facing of fireplaces and saunas. The good resistance of travertine to heat makes it possible to use it in areas with high temperatures.

- Production of interior elements. Travertine is often used to make window sills, kitchen table surfaces, bar counters and other work surfaces. In addition, figurines and vases are made of natural stone.

- Use in humid areas. With proper processing, natural travertine has low water absorption and can be used to create bathtubs, sinks and shower trays. Tiles made of this material are also used in the decoration of swimming pool bowls.

It is worth noting that for all its durability, natural travertine can quickly lose its appeal without proper care. The polished surface of this stone can be easily scratched with sand or other abrasives, which is why you should not walk on such a floor covering in street shoes. Aggressive detergents should not be used to clean travertine from dirt, as this material is vulnerable to acid exposure. If necessary, the appearance of the travertine coating can be restored, however, such work will require the participation of qualified specialists equipped with the necessary equipment.

- Facing and decorative materials - sale, production

- Travertine - sale, production

- Liquid travertine - sale, production

- Raw materials for travertine - sale, production

- Products from travertine - sale, production

- Table top from travertine - sale, production

- Window-sills from travertine - sale, production

- Plate from travertine - sale, production

- Columns from travertine - sale, production

- Steps from travertine - sale, production

- Artificial travertine - sale, production

01.12.2025