SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV in Jalakuduk

- Information

- Products / services

- Types of activity

- Work time

- Feedback

Contact information of the organization/company SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV - Jalakuduk (phone numbers, location, working hours, activities and other useful information). If this data helped you to contact this organization, please let them know that you found their contacts on the website of the business directory of Uzbekistan: Golden Pages - Uzbekistan

Additional information about organization and they activity

JV «SPZ-BEARINGS» (former GPZ-27) was built and launched into production in 1986.

This is the only plant in Uzbekistan specialized in the production of roller and ball bearings for various industries:

• railway industry;

• mining industries;

• metallurgical plants;

• chemical and oil and gas industries;

• hydroelectric power plants;

• the Ministry of Agriculture;

• automotive industry and national economy.

The bearing plant JV «SPZ-BEARINGS» has the necessary technical knowledge and significant resources for the production of railway bearings and axle boxes for rolling stock of railway transport.

One of the main achievements of the bearing plant JV «SPZ-BEARINGS» is the development of the production of axle box bearings: 36-42726E2M, 36-232726E2M, H-882726E2K1MUS44, tapered bearings of cassette-type axle box units TBU 150x250x160, TBU 130x250x160 and TBU 130x230x150 of passenger and freight cars of rolling stock.

An international EAC certificate has been received for railway axle box bearings of type 36-42726E2M, 36-232726E2M and tapered bearings of cassette type axle box units TBU 150x250x160, 130x230x150.

Today, the bearing plant SPZ-BEARINGS produces more than 1200 types of bearings.

• Ball radial;

• Ball radial spherical;

• Roller radial;

• Roller radial spherical;

• Roller radial with short cylindrical rollers;

• Radial roller with twisted rollers;

• Radial thrust ball;

• Tapered roller;

• Thrust or thrust-radial ball;

• Thrust or thrust-radial roller.

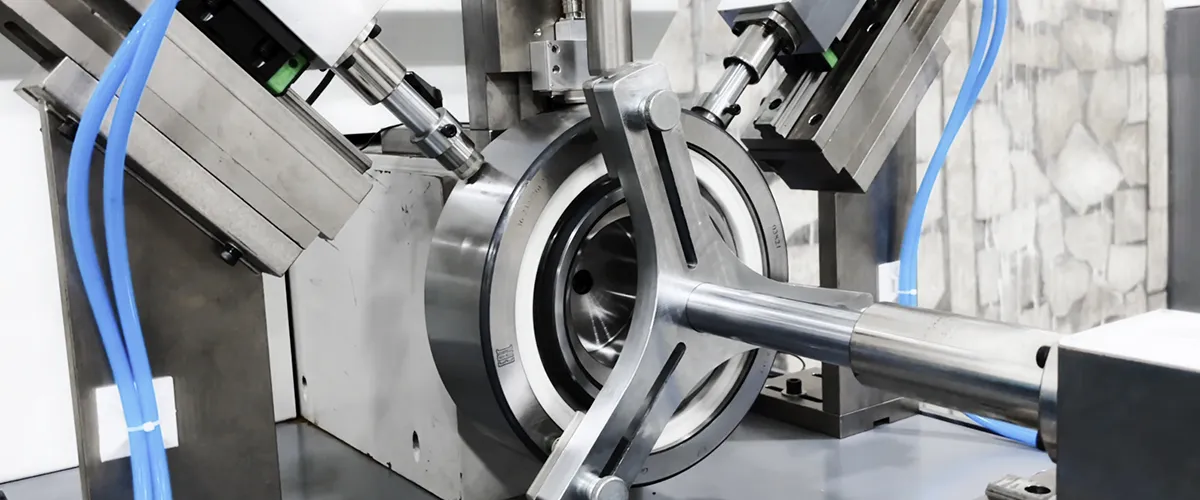

The plant's production infrastructure is represented by 8 main production workshops, there is an engineering communications and a huge machine park which consists of more than 500 modern high-precision production machines:

• automatic lathe shop;

• compressor shop;

• stamping shop;

• heat shop;

• separator shop;

• assembly shop;

• ball shop;

• grinding shop.

The bearing plant JV “SPZ-BEARINGS” is the only enterprise in Central Asia producing tapered and spherical roller bearings.

The bearing plant JV “SPZ-BEARINGS” is part of the Non-profit organization Union “Inter-Republican Concern “Podshipnik”, Russia.

The bearing plant JV “SPZ-BEARINGS” designs and manufactures non-standard and unique bearings according to individual customer orders.

Our own forging, foundry and tool production allows the enterprise to control quality at all stages of the technological cycle: from the purchase of raw materials to the production of components and assembly.

The enterprise has technical and design departments consisting of highly qualified specialists who develop and improve products based on modern engineering solutions.

The enterprise has a quality system in accordance with ISO 9001:2015 standards. All products of the enterprise have a quality certificate, a certificate of conformity and hygienic certificates.

The plant has a certified centralized laboratory equipped with all the necessary devices and equipment for checking and testing manufactured products according to all technical parameters. We are constantly working to improve the quality of not only the products themselves, but also their service support. Our technical specialists provide advice on the operation of bearings, their maintenance, and study the individual production features of our customers.

To ensure the competitiveness of bearings of SPZ-BEARINGS and to achieve a modern level of quality, the bearing plant, with the help of the scientific and technical center, implements a technical policy aimed at improving the design of bearings, using new materials, processes and technologies, updating technological equipment, tools, mastering the experience and achievements of domestic and foreign science.

To ensure the quality of manufactured products at a high level, the bearing plant of SPZ-BEARINGS carries out incoming inspection of received materials in accordance with STP 048-2569-22:

1. Evaluation of compliance of purchased materials and semi-finished products with established requirements.

2. Spectral (qualitative and quantitative determination of material composition) and metallographic (microstructure analysis) analyzes of metal are carried out in the central plant laboratory on the most modern equipment.

3. In the mechanical testing laboratory, the hardness of bearing parts is determined and tensile tests of metal are carried out.

Foundry production

The foundry shop prepares metal for the production and repair purposes of the plant

The technological equipment of the foundry shop allows for the production of blanks from ferrous and non-ferrous metals, ensuring high strength of the products.

Feeding of molding mixtures by conveyors

Turning is carried out on turning equipment with a new generation of numerical program, the main feature of which is the movement and rotation of manipulators with working tools around a fixed blank.

The production of separators at the bearing plant of the joint venture "SPZ-BEARINGS" is carried out on unique modern equipment - a vertical milling machining center with CNC, which allows for high quality products.

Forging production

The own forging production of the joint venture "SPZ-BEARINGS" with unique multi-profile equipment allows for the production of open-die forgings, stamped blanks, rolled rings and other products of forging production necessary for the production of bearings.

Tech. control

Technological control is continuous control of all specified values and parameters of the technological process during production.

Interoperational control of each batch of products during its production according to strictly specified quality criteria, until the end of the production cycle.

100% control of each finished product.

The unique equipment of SPZ-BEARINGS allows for the production of non-standard (according to individual customer orders) bearings with a diameter of up to 1.5 meters and a weight of up to 1.5 tons.

Plant modernization

Ensuring the quality of bearings manufactured at the bearing plant of the joint venture “SPZ-BEARINGS” is one of the main tasks, the solution of which determines the competitiveness of products in the domestic and international markets.

In this regard, the plant is constantly undergoing a process of technical re-equipment. Measures are being implemented to modernize production, introduce new technologies. In 2014-2024, the enterprise purchased and re-modernized over 150 units of modern, high-tech equipment, which allows to significantly increase the efficiency of production areas.

Services are licensed, products are certified.

The advertiser is responsible for the accuracy of the advertising material.

Products / services - SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV

Types of activity - SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV

Working hours - SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV

Feedbacks about the company SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV

[February 2026 year]

[January 2026]

[November - January]

[February 2025 - January 2026]

[since 06.07.2011]

SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV is often found for the following searches:

-

Where is SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV located?

SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV is located at the address: Uzbekistan, 171100, Andijan region, Jalakuduk, Karasu Street, 3

-

Phone number SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV?

You can call SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV at 74 7551857; 74 7552359

-

What is the operating mode of SPZ-BEARINGS. LTD UZBEKISTAN-RUSSIA JV

- Mo: ⌚ 08.00 - 17.00 Lunch: 12.00 - 13.00

- Tu: ⌚ 08.00 - 17.00 Lunch: 12.00 - 13.00

- We: ⌚ 08.00 - 17.00 Lunch: 12.00 - 13.00

- Th: ⌚ 08.00 - 17.00 Lunch: 12.00 - 13.00

- Fr: ⌚ 08.00 - 17.00 Lunch: 12.00 - 13.00

- Sa: ⌚ weekend

- Su: ⌚ weekend